The area of one panel is (m2) 12 m

Total panel area (m2 ) 624

Loading rates for a container

The internal volume of a 40-foot container is 67.3-67.8 m3.

The maximum carrying capacity is 24.8-26.8 tons.

The weight of a 40-foot container without cargo is 3,640-4,000 kg.

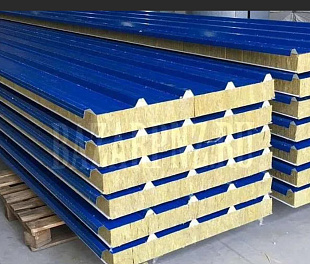

Sandwich wall panels made using mineral wool have gained popularity in the construction of prefabricated buildings. This applies to both the industrial sector and shopping centers, warehouses and other buildings. The functions of a heater are performed by mineral wool boards produced by DoorHan enterprises - they are based on rocks of the basalt group.

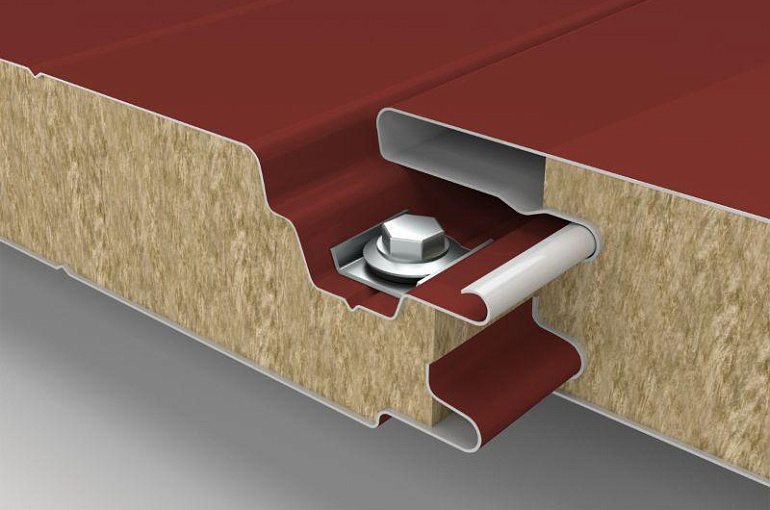

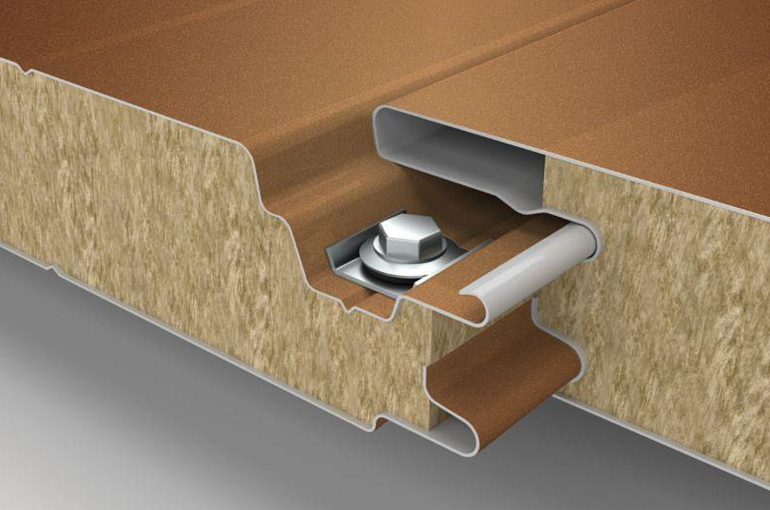

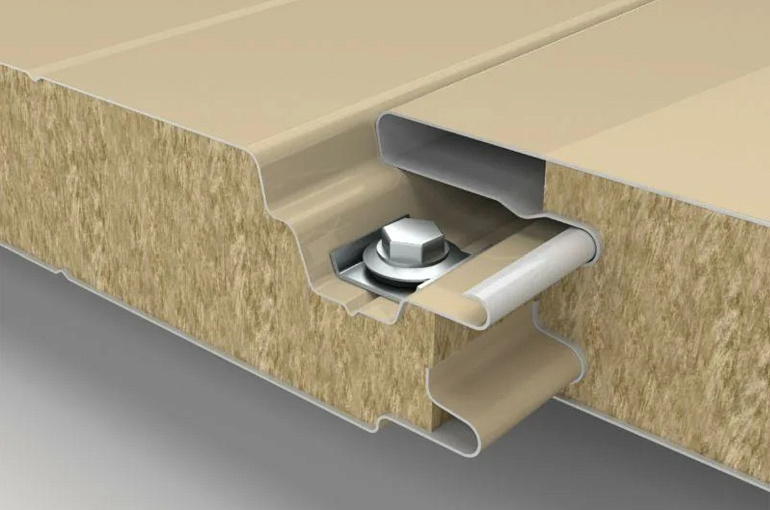

PIR – inner core is an advanced thermoset polyisocyanurate (PIR) foam which is sandwiched between two layers of embossed aluminium foil facings.Sandwich panels are made of hot-dip galvanized sheet steel, which is manufactured using cold-rolled steel. Building materials are made from steel with a thickness of 0.45 to 0.7 mm - the type of polymer coating may differ. Dorkhan mineral wool slabs, obtained on the basis of basalt rocks, act as the core. The connecting element between the core itself and the metal used for cladding is a two-component polyurethane adhesive.

CHARACTERISTICS

Flammability class G1

Polyester cover

Cladding type smooth

Panel thickness H 200 mm

Working width 1000 mm

Metal thickness 0.5 mm

Weight of zinc coating, 275 kg/m2

Panel facing metal thickness, 0.5 mm

Mineral wool density, kg/m³ 130

Specific weight of the panel* 217.2 kg/m2

Thermal conductivity coefficient, W/(m K) 0.042-0.043

Reduced resistance to heat transfer, not less than R0, m2°С/W6.99 m2°С/V

Dimensions (custom sizes available):

|

Indicator name

|

Unit rev.

|

Value

|

|

|

Thickness

|

mm

|

20; thirty; 40; 50; 60; 70; 80; 85; 90; 100

|

|

|

Length x width, with “L” -edge **

|

mm

|

2385×1185, 1185×1185, 1185×585

|

|

|

Length x width, without “L” -edge

|

mm

|

2400х1200, 1200х1200, 1200х600

|

|

Basic physical and mechanical characteristics:

|

Indicator name

|

Unit rev.

|

F / F

|

CXM / CXM

|

|

|

Thermal conductivity, no more, at:

(25 ± 5) 0 С

operating conditions A

operating conditions B

|

W / (m * K)

|

0.021

0.022

0.023

|

0.023

0.025

0.026

|

|

|

Compressive strength at 10% linear deformation, not less

|

kPa

|

120

|

|

|

Water absorption by volume during long immersion

(28 days), no more

|

%

|

1.0

|

|

|

Operating temperature

|

o C

|

from – 65 to + 110

|

|

|

Flammability group

|

–

|

D1

|

G4

|

|

PIR-based heat-insulating material belongs to a special class of thermosetting polymers with a gas-filled closed cell structure containing a permanent inert gas responsible for reduced thermal conductivity. One of the features of PIR is its specific chemical structure, which is characterized by a combination of a rigid ring molecular structure and strong high-density chemical bonds. These features provide increased thermal resistance of the insulation, as well as resistance to fire. The carbonizing substance on the surface of the material when exposed to flame leads to the formation of a “porous” protective carbon matrix, which prevents further thermal decomposition of the inner layers of the polymer, contributing to the preservation of the integrity of the building structure with PIR. Thermal insulation boards PIR have a long service life, due to the fact that they have minimal water absorption, are not subject to the destructive effects of aggressive media, as well as decay, incl. in high humidity conditions. PIR boards have straight or molded ends in the form of an “L” -edge to improve the joining of the material to each other and create a continuous thermal insulation loop without cold bridges.

Advantage of PIR plates:

- Not flammable

- 100 % eco-Friendly

- Rigidity that allows the use of sandwich panels on floors

- Simple installation. It can be installed without heavy equipment, using conventional winches

- Fasteners for self-tapping screws and mounting foam.

- Foam thickness of 115 mm annually saves 162 kWh per 1 sq m

Application of PIR insulation on a metal basis. Interior finishing with drywall or directly on the metal. To protect products from damage during the delivery process, the plates are packed in special transport bags with foam.

Application area: Heat-insulating PIRs are used in civil and industrial construction when installing flat roof systems on metal and concrete bases with adhesive or mechanical fastening. Also, PIR thermal insulation boards can be used to insulate floors (including loaded ones) and facades.