Availability: 2754 sheets

Certified FSC 100% – Formaldehyde Free 100% – ECO Board – Moisture Resistant – Load-bearing. OSB-3 - load-bearing boards in high humidity conditions. E-0.1 emission class. Below you can find technical information from Manufacturer.

Kalevala-EcoDom.

Environmentally friendly building material

Kalevala-EcoDom are sheets made using an environmentally friendly adhesive that does not contain formaldehyde for construction and use in interior decoration.

In the production of Kalevala-EcoDom plates, raw materials are used:

-

FSC-certified northern softwood pulpwood (license code FSC-C123880);

-

Paraffin emulsion, providing the plate with moisture resistant properties;

-

Environmentally friendly adhesive system;

-

Water;

-

High-tech equipment guarantees stable quality indicators of Kalevala-Ekodom slabs;

Application areas of Kalevala-EcoDom:

-

Interior decoration;

-

Constructions of residential and public buildings;

-

Products and structures operated inside residential premises;

-

Packaging production;

-

Furniture manufacture.

-

The physical and mechanical characteristics of Kalevala wood boards - EcoDom - comply with the requirements of regulatory and technical documentation for OSB-3 type wood boards.

About OSB Kalevala.

OSB, Oriented Strand Board is the material formed by pressing of flat wood chips of softwood with the use of safe and high quality adhesive.

OSB is the latest development in the field of deep wood processing for making the product of unique physical and mechanical properties.

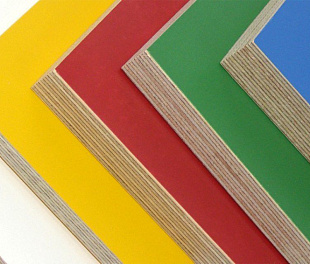

Board manufacturing is a continuous process of pressing with the use of high temperature and pressure. The board consists of 3 layers: chips in the layers are placed in parallel to each other and perpendicularly to the chips in the neighboring layers.

Thickness of chips – 0,65 mm, width – 5-25 mm, length – 75-125 mm. Dimensions, shapes and orientation of chips in separate layers allow achieving the best physical and mechanical properties of the boards. Construction material of high bending strength and elasticity along the major axis of the board is achieved due to such orientation of flat chips.

The products of the wood processing mill Kalevala satisfy the highest requirements of environmental safety.

All quality indices of OSB Kalevala comply with the European standard ЕN-300-2006 («Oriented Strand Boards (OSB) - Definitions, classification and specifications»).

OSB contains up to 90% of wood, fraction of adhesive in the composition of the board amounts to 10%. It provides environmental safety of the material and preserves the performance properties of wood: lightness (density of OSB – about 650 kg/cubic meter) and low heat conductivity.

Actually, OSB is “enhanced wood”: stronger and more elastic due to preserving all useful properties of solid wood in flat chips. The technology of pressing and the composition of adhesive exclude the possibility of board exfoliation. OSB has no such common defects of wood and veneer as knots, internal voids and exfoliations.

Qualitative characteristics of OSB:

- Environmental compatibility

- Stability of shapes and dimensions

- Bending strength

- Resistance to deformation

- Simplicity of cutting and assembling

- High heat and sound insulation properties

- High wear resistance

- Uniformity of structure

OSB Kalevala comply with the requirements of the Specifications 5534-001-79787960-2013.

The Specifications (ТУ 5534-001-79787960-2013) consider basic technical requirements for the boards in accordance with the European standard EH 300:2006

OSB has become especially popular in producing roof and wall sandwich panels for skeleton-type house building. Its application reduces the time of building and at the same time making it more accurately.

OSB is used for constructions, where transfer of load to lengthwise bearing (for example, trussing and beams) is necessary.

Thus, OSB can be applied as a bearing base for flexible tiles, roll materials and seam roofing. For application of heavier coverings, such as ceramic and cement-sand tiles, OSB becomes a surface of wind bracing, which means that load is reallocated along the surface of the board. OSB-3 is widely used for mounting of solid roof sheathing. OSB-3 is listed in the recommendations of the manufacturers of flexible tiles in Europe.

General fields of OSB application

- Sheathing of partition walls

High strength and resistance to deformation make possible to apply OSB in combination with multiple types of exterior and interior lining coating.

- Base for roof coverings

Such properties as lightness, sound absorption, rigidity and capacity to withstand heavy snow and wind loads make OSB suitable for application as a base for roofing materials. OSB ensures high pull-out resistance of screws, which increases reliability of roofing materials.

- Supporting joists and floor coverings

OSB is used in building for construction of supporting surfaces (such as solid coverings and bearing joists). For lightweight building constructions OSB is used as basic flooring, with application of self-leveling lightweight concrete mixture or under flooring boards.

- I-beams

High quality supporting OSB constructions prevent displacement and deflection; I-section contributes to the solidity properties, which rank I-beams together with concrete and reinforced-concrete constructions.

- Furniture and packaging

OSB is used for production of the components of high-loaded furniture frames as well as for production of packaging: crates, boxes and containers.

- FSC certification of OSB

The enterprise passed the certification test under FSC system for compliance with the standards of FSC-STD-40-004 “Standard for Chain of Custody Certification” and FSC-STD-40-005 “Standard for Company Evaluation of FSC Controlled Wood”.

Physical and mechanical properties of OSB-3 Kalevala

Load-bearing boards for use in humid conditions within physical and mechanical properties shall comply with the requirements specified in the table as follows:

|

Property

|

Requirement for board thickness range (mm, nominal)

|

|

9

|

|

Bending strength - major axis of board, MPa, not less

|

22

|

|

Bending strength - minor axis of board, MPa, not less

|

11

|

|

Modulus of elasticity in bending - major axis of board, MPa, not less

|

3500

|

|

Modulus of bending elasticity - minor axis of board, MPa, not less

|

1400

|

|

Tensile strength perpendicular to the plane of board, MPa, not less

|

0,34

|

|

Swelling in thickness for 24 h., not more

|

15%

|

Nominal dimensions of OSB Kalevala

|

Dimension

|

Size, mm

|

Ultimate deviation, mm

|

|

Thickness

|

9,0 with gradation of 1,0

|

± 0,8*

|

|

Length

|

2500

|

± 3,0

|

|

Width

|

1250

|

± 3,0

|

|

* both within one board and a line of boards

Notes:

- Length is defined as a side aligned with the major axis due to its direction,

- Width is defined as a side aligned with the minor axis due to its direction,

- Upon agreement with the customer, board production of length and width dimensions, not specified in the table, is possible.

|

Load-bearing OSB-3 Kalevala for use in humid conditions is bound to be verified for moisture resistance.

Requirements for moisture resistance of OSB-3 Kalevala

|

Measurement properties of board moisture resistance

|

Board type

|

Requirement for board thickness range (mm, nominal)

|

|

9

|

|

Tensile strength perpendicular to the plane of the board, MPa, not less (Тн)

|

OSB-3

|

0,15

|