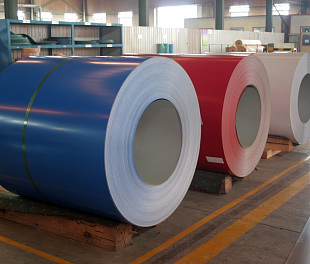

Number of running meters in a coil 50

Roll weight 11 kg

Coil diameter Ø 1,2 m

Coil height 10 cm

Tensile modulus, GPa not less than 55

Tensile strength, GPa not less than 1.2

Loading rates for a container

The internal volume of a 40-foot container is 67.3-67.8 m3.

The maximum carrying capacity is 24.8-26.8 tons.

The weight of a 40-foot container without cargo is 3,640-4,000 kg.

Standard fiberglass composite reinforcement is packed:

in bays of 50-100 running meters for reinforcement with a diameter of 4-12 mm, over a diameter of 12 mm - in whips; whips of 1, 2, 3, 6 p.m. Whips for ease of transportation, can be supplied rolled into coils (for fittings with a diameter of 4 - 12 mm). By agreement with the Customer, it is possible to manufacture whips and bays of any length.

Please email us for placing the order/ This item is currently only available for pre-order. Although we appreciate custom requests, please note that we cannot fulfill orders in small quantities as it is exported from Europe, Minimum order quantity: 1 x 40 ft container. Terms of delivery: FCA

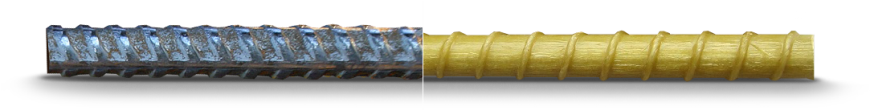

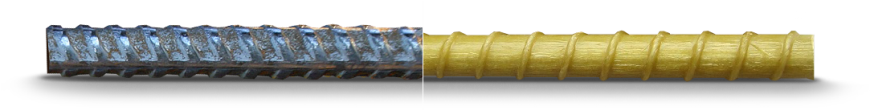

Fiberglass composite reinforcement is a rod with a continuous spiral relief (to improve adhesion to concrete), of any construction length and an outer diameter of 4 to 18 mm. It consists of glass fibers (glass roving) bonded with a polymeric synthetic binder based on epoxy resin. In terms of tensile strength, fiberglass reinforcement Ø 12 mm is not inferior to steel Ø 14 mm and is quite capable of replacing it. In addition, fiberglass reinforcement 12, the price of which is approximately two times lower than that of metal, is cheaper in transportation and assembly of reinforcing frames.

If we talk about the advantages of this fitting, then they are as follows:

Light weight (5-8 times less than steel bars of the same diameter), which facilitates both handling and transportation of the bars.

Low thermal conductivity (almost 100 times lower than that of steel), which reduces the heat loss of a concrete structure reinforced with composite rods.

Environmental friendliness - does not emit toxic substances.

Radio transparency - does not interfere with radio waves, cellular communications.

The durability of fiberglass is 50-80 years.

Absolute corrosion resistance.

Tensile strength is 2-2.5 times greater than that of metal.

It can be operated in the temperature range from -70 to +200 degrees.

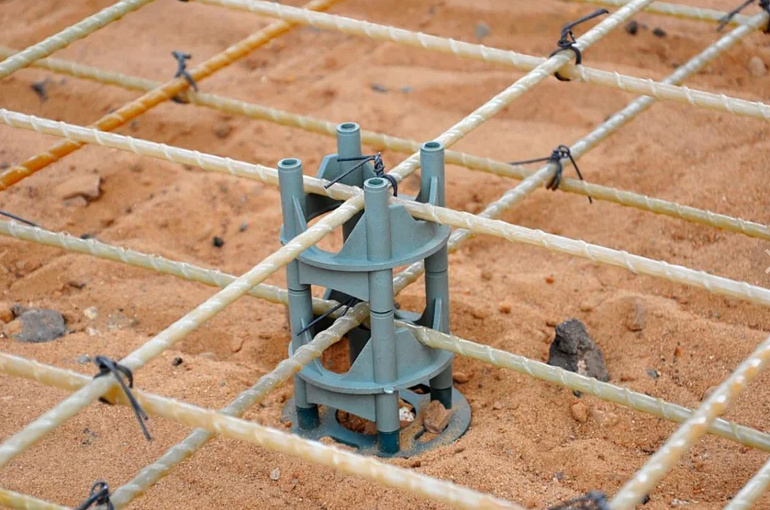

Reinforcement is made without welding - the glass composite is simply tied with wire or plastic clamps.

Does not conduct electricity.

Reinforcement is sold both in the form of rods and bays, which allows you to cut it into pieces of the required length. This greatly reduces the amount of waste.

Composite reinforcement should be used: As grids and rods in structures; When reinforcing bowls of pools and fountains. The use of non-metallic reinforcement increases the service life of structures by 2-3 times compared to the use of metal reinforcement, especially when exposed to aggressive environments, including those containing chloride salts, alkalis and acids.

At this point in time, in the production of construction work, certain types of it are most often used.

ASK - fiberglass composite reinforcement;

ASP - fiberglass polymer reinforcement;

AUK - carbon composite rebar;

AKK - combined composite reinforcement.

Having bought composite reinforcement, for example, in a 100 meter coil, you can cut off whips of any length you require from it, which will reduce the amount of waste and save you from the need to splice individual rods of standard length (6 or 12 meters) along the length;

Buying fittings in bays (coils, coils), you can save on transport, since you do not have to order transport with a long body length and with a large load capacity;

After unwinding the coil with composite reinforcement, it is not necessary to straighten it! It straightens itself, its behavior is similar to the behavior of a spring. The thicker the diameter of the rebar wound into the coil, the more carefully you need to unwind it.