Loading rates for a container

The internal volume of a 40-foot container is 67.3-67.8 m3.

The maximum carrying capacity is 24.8-26.8 tons.

The weight of a 40-foot container without cargo is 3,640-4,000 kg.

CLASS – GL24, GL28

ACCORDING EN 14080, EN 14081, EN 4074

STANDARD LENGTH– 8 / 9 / 10 / 12 / 13 / 13,5 М

Standard beam sections: 80/100/120/160/200/240/280 x 120/160/200/240/280/320/360/400/440/480/520/560/600

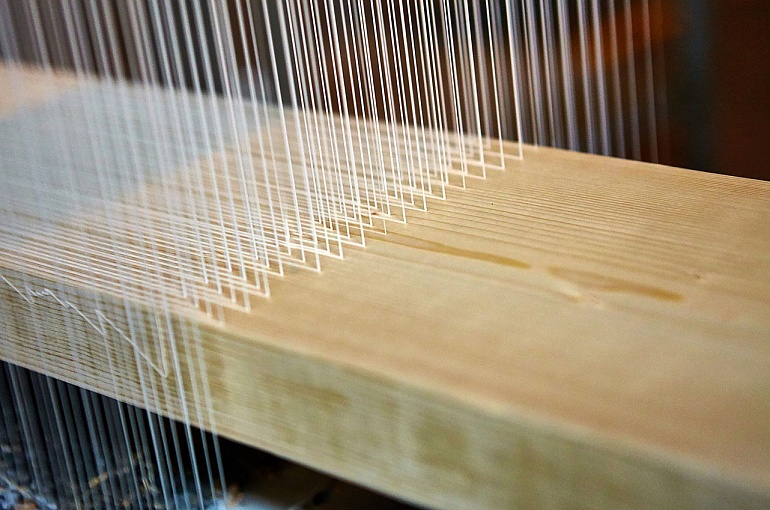

Three-lamellar and multi-lamellar pine glued laminated timber (moisture resistant glue D4), 10-12% humidity, class AB

Standard lengths: 12000/12500/13000/13500

Standard sections of the timber:

W-shaped profile (14mm): 230 (h) x 125/160/205/235 mm., 280 (h) x 160/205/235 mm.

W-shaped profile (wide spike) (11mm): 230 (h) x 145/200 mm., 280 (h) x 145/200/255 mm.

U-shaped profile (11mm): 230 (h) x 160/205/235 mm., 280 (h) x 160/205/235 mm.

Timber quality control is implemented by the EA702 microtec system with XR module, which automatically arranges wood using laser and x-ray scanning by strength classes c16-c45.

Australian standard sizes available:

130/165/195/230/260/295/330/360/395/425/460/495 x 65

130/165/195/230/260/295/330/360/395/425/460/495/525/560/590 x 85

130/165/195/230/260/295/330/360/395/425/460/495/525/560/590 x 130

Glued laminated timber, also abbreviated glulam, is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives.

A glue-laminated timber is an engineered wood product, meaning it is made from wood but is machined and assembled to precise specifications to create a predictable, dimensionally stable building material. Other common engineered wood products include plywood, oriented strandboard (OSB), and laminated veneer lumber (LVL). A glulam beam looks like a stack of 2 x 4s (or larger lumber) glued together on their broadsides. This contrasts with other engineered members, such as LVL (laminated veneer lumber) and Microlam beams, which look like very thick plywood, with very thin layers of wood glued together to form a thicker mass.

Glulam members are sold in several standard widths and lengths and can be custom fabricated to meet almost any design specifications. They are commonly used for large curved or arching members to build vaulted roofs, domes, and even bridges. Glulam construction offers superior strength and stiffness over dimensional lumber, and pound-for-pound it is stronger than steel. Connections for glulam beams are typically made with bolts or steel dowels and steel plates.

Advantages

Unique dimensions: Thanks to its high load capacity and low weight, Glulam allows you to cover large areas with small components. It can cover sections of up to 100 meters without intermediate support.

Resistance: Successfully resists various chemicals. It also resists transformations caused by moisture, such as deformations and/or torsions.

Flexibility: Curved, arched, and folded shapes are reproduced quite easily. Pieces also don’t necessarily need to follow the geometry of the tree trunk.

High fire resistance: Structures made of glued laminated wood are safer than unprotected steel in fire. This is because a carbonized layer forms around the Glulam’s core, decreasing oxygen consumption and retarding combustion.

Dimensional stability: Glulam has a humidity of 12%, which corresponds to an equilibrium humidity of 20°C and 65% relative humidity. Contraction and swelling behavior is therefore minimized.

Less need for connections: These structures may require a smaller number of joints when covering large openings without intermediate supports.

Lightness: This feature eases maintenance and assembly/disassembly. Studies show that a Glulam beam has the same strength as a concrete beam of the same volume, yet the weight of the piece of wood is approximately five times less.