Availability: 3380 sheets

Pack quantity (sheets) 72

Pack weight (kg ) 12,5

Current sizes available:

2440 x 1220 x 9 mm – $35 /sheet (or $12.09 \ M2)

Formaldehyde Free 100% – ECO Board – Moisture Resistant – Load-bearing. E-0.1 emission class.

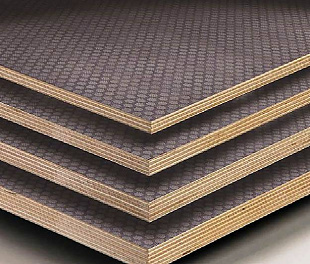

Oriented strand board, also known as OSB or OSB Board, is an engineered wood product formed by layering strands (flakes) of wood in specific orientations. Similar if not superior properties to MDF (Medium Density Fiberboard), MDP (Medium Density Particleboard) and other particle boards.

It is manufactured in wide mats from cross-oriented layers of thin, rectangular wooden strips compressed and bonded together with wax and resin adhesives (95% wood, 5% wax and resin).

Each layer is laid perpendicular to the previous in order to maximise the strength of the finished product. Once the desired thickness has been achieved, the strands are heated and pressed together to result in a board that is strong, thin, durable and flexible.

The mat is placed in a thermal press to compress the flakes and bond them by heat activation and curing of the resin that has been coated on the flakes. Individual panels are then cut from the mats into finished sizes

When made from timber scraps or recycled wood, OSB is more environmentally friendly than plywood. Even when made from harvested timber, OSB tends to be the more environmentally friendly option. This is due to the small strips of wood it requires; young, fast growing timbers can be used, including pine and even bamboo.

OSB Usage

- sheathing of interior and exterior walls. OSB panels can be used with all types of interior and exterior finishing materials

- roof sheathing. Good sound insulation, high stiffness and ability to withstand significant snow and wind loads allow to use OSB panels as an underlayment for shingles, concrete and metal tiling, slating and other roofing materials

- I-joists – supporting floor and wall structures in timber houses.

- Manufacturing of SIP panels consisting of two outer OSB layers and a core polystyrene foam layer

- stiff basis for thermal panels

- removable formwork for concrete works (multi-use formwork), concrete platforms. Sanded and overlayed OSB panels can be used repeatedly as a concrete formwork

- subfloor, floor repair. OSB can be used both as continuous flooring and load bearing joists

- single floor – in light structures OSB panel can be used directly as flooring

- furniture –frames of upholstered furniture, chairs, cabinet furniture, home built-in furniture (coat closets, shelving units, wall wardrobes)

- stairs, landings, scaffoldings

- temporary construction site fencing, coverings for structural openings (windows, doors)

- shipping crates and pallets, shelving units, exhibition stands, furniture shelves, shop counters, table tops, bill boards;

- partition walls for ships and railcars

- structures for auto vehicles, trailer floorings and truck bodie.

OSB Quality Features:

- Durability

- Easy cutting, processing and usage

- High sound insulation (sound absorption) performance

- Low thermal conductivity

- Suitable for humid conditions

- Rot-fungi-and-bio resistance

- High fire resistance.

Technical Parameters of OSB (from the manufacturer):

|

Property

|

Standard value for 9 mm thick boards (nominal)

|

|

MOR, Major Axis, MPa, min.

|

22

|

|

MOR, Minor Axis, MPa, min.

|

11

|

|

MOE, Major Axis, MPa, min.

|

3500

|

|

MOE, Major Axis, MPa, min.

|

1400

|

|

Tensile strength perpendicular to the board’s surface, MPa, min.

|

0,34

|

|

Thickness swelling/24hr., min.

|

15

|

- Oxley Trade is one of the key suppliers of Oriented Strand Board (OSB) in Australia – if you have any questions, please get in touch!